How To Repair Abs Control Module 08 G6

Anti-lock braking organization (ABS 8.0 and ABS eight.0 ESP)

General

From MY 2004, the Corsa-C, in all engine variants, volition be fitted with the new anti-lock braking organisation, ABS 8.0.

ABS 8.0 is a modular system, with 8 solenoid valves. In its basic form it is the same every bit ABS 5.three and is also available with ESP as an choice.

With the introduction of ABS 8.0 ESP, Opel vehicles will, for the kickoff time, exist taking the "braking system temperature" parameter into account in the braking system control strategy.

By measuring the temperature in the hydraulic unit, a map can be calculated to make up one's mind whether there is a risk of the braking system overheating, for example, on downhill runs.

The ABS control unit/hydraulic unit associates has been modified. The weight of the ABS command unit/hydraulic unit has been reduced by 25% by using mod microprocessor technology. At the same fourth dimension, the exterior dimensions have been changed, thus reducing the volume of the assembly by 30% compared with ABS 5.3.

Thanks to its horizontal installation position in the Corsa-C, the ABS control unit of measurement can be detached from the hydraulic unit whilst yet installed.

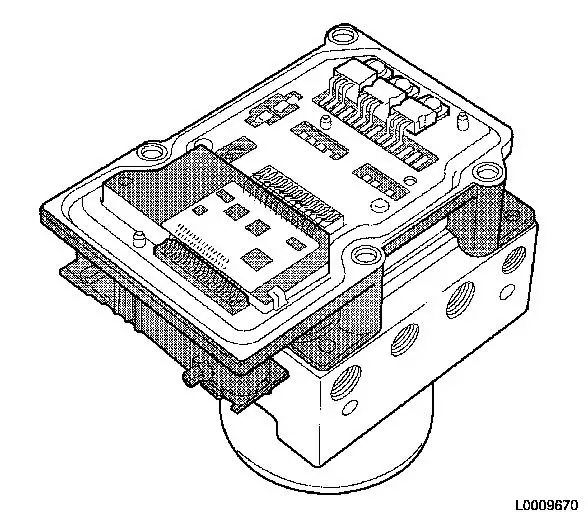

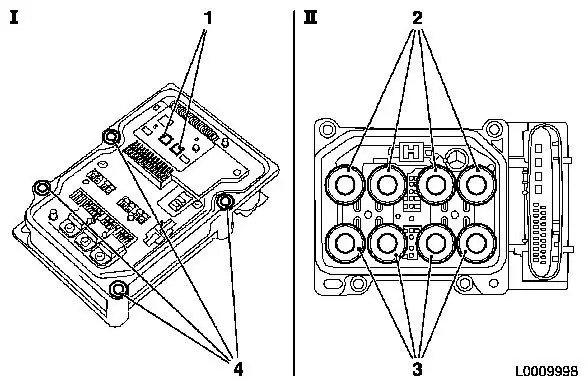

ABS control unit of measurement/hydraulic unit assembly

| ||||||||

| ||||||||

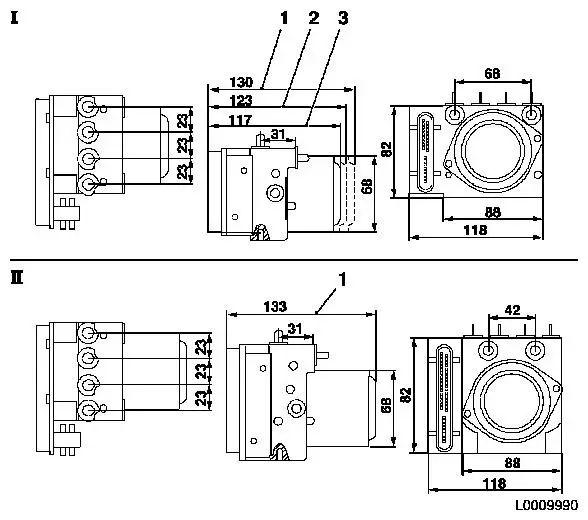

From an appearance point of view, the ABS 8.0 and ABS 8.0/ESP do not just differ in size.

The bore of the hydraulic connections on the ABS control unit of measurement coming from the chief cylinder is smaller on the ABS viii.0 than on the ABS 8.0/ESP.

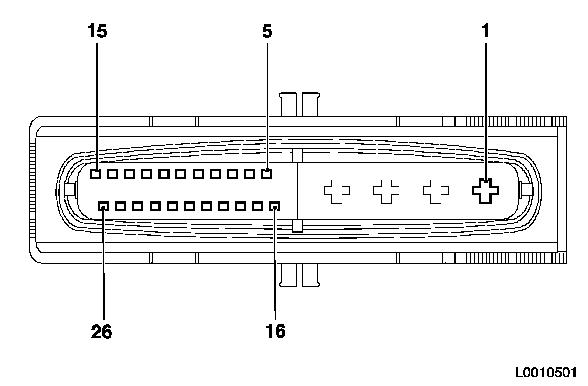

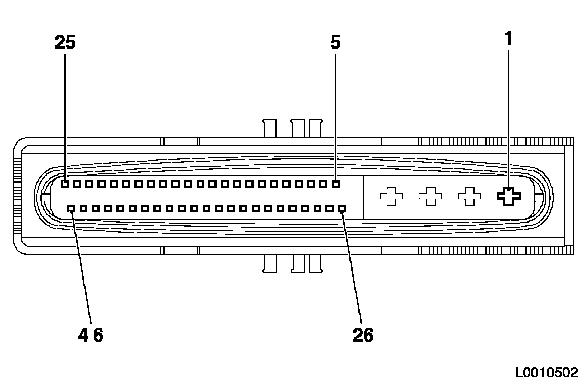

The electrical connection on the ABS command unit is a 26-pin connexion on the ABS 8.0 and a 46-pin connection on the ABS 8.0/ESP.

Dimensions and weight

The weight of the ABS 8.0 also varies depending on the version.

| ABS 8.0 (XS engine) | ABS v.3 | |

| Dimensions | ||

| Width x top x length | (118 x 80.3 ten 113.6) mm | (84 10 118 x 170) mm |

| Book | one.ane litres | i.seven litres |

| Weight | ane.half-dozen kg | 2.6 kg |

| ESP 8.0/ESP (S/50 engine) | ABS 5.3 TCS/ESP | |

| Dimensions | ||

| Width x elevation x length | 118 x 103 ten 132.v) mm | 84 x 138 x 183 mm |

| Volume | 1.seven litres | ii.1 litres |

| Weight | 2.3 kg | 3.two kg |

| ||||||||

| Versions

|

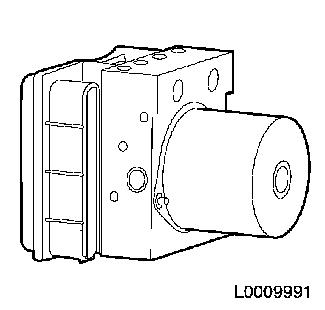

Installation location

| The ABS command unit/hydraulic unit assembly is installed horizontally (1) in the Corsa-C. The motor of the hydraulic unit of measurement is installed with its shaft in a horizontal position and the connections of the individual restriction circuits face upwards. The advantage of this installation position is that the ABS control unit of measurement tin be removed for assembly or repair work without having to remove the entire associates. |  |

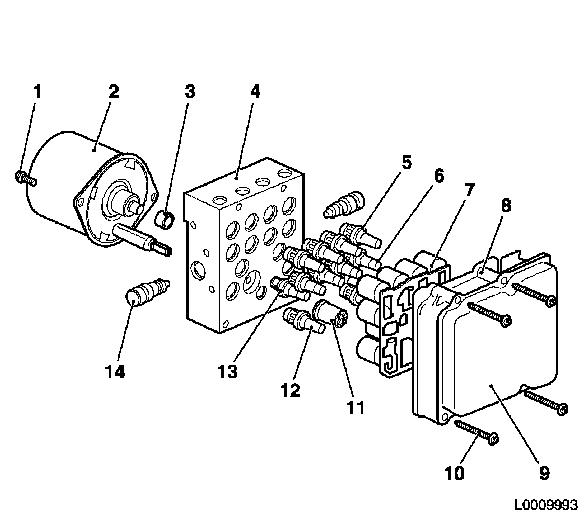

Exploded diagram

| ||||||||||||||||||||||||||||

|

| ABS control unit |

|

| The control unit of the ABS 8.0 is based on the latest pulse line and chip technology and is designed to connect to four active or 4 passive cycle sensors. Agile wheel sensors are used on the Corsa-C. The regulation and control function of ABS 8.0 is safeguarded by two dissever microprocessors (1). Each of these microprocessors tin exist reprogrammed. The individual components of the ABS control unit are not replaceable. If there is a fault, the entire ABS control unit has to exist replaced. The pump motor in the hydraulic unit of ABS 8.0 is actuated via the pump housing. The solenoid valves to the hydraulic unit are actuated by magnet coils. These magnet coils are connected directly with the semiconductor relay in the ABS control unit and are therefore incorporated into the ABS control unit. The ABS control unit of measurement is connected to the hydraulic unit via four fastening bolts (4) and can be detached and removed from the hydraulic unit in the vehicle. |

• Service:

For repair piece of work it is possible to replace the ABS command unit and the hydraulic unit separately.

The hydraulic unit is supplied "pre-filled" from the Service department. The seal of the ABS control unit is not bachelor separately. If there is a leak between the hydraulic unit of measurement and the ABS command unit of measurement, the entire ABS control unit/hydraulic unit must exist replaced.

Atmospheric condition for replacing the ABS control unit:

- The ABS control unit should just be replaced with a new one if the unambiguous diagnosis consequence "ABS control unit of measurement fault" (when diagnosing with Tech ii and error code "Faulty control unit" is present) is obtained or if there is visible damage to the housing or the connector of the ABS control unit.

- If the ABS control unit of measurement is detached from the hydraulic unit whilst even so in situ, ensure that the surrounding area is kept clean as even the smallest amount of dirt in the hydraulic unit of measurement'south valves tin can cause malfunctions.

- Under no circumstances must the cover of the ABS control unit be pushed in. This will cause harm to the ABS control unit that will non be visible from the outside. When installing just agree the ABS control unit on the outside border of the housing. Practice not use force when installing the unit.

- Nether no circumstances should the ABS control unit of measurement be attached to the hydraulic unit with fastening screws. This will cause damage to the ABS control unit and/or the hydraulic unit.

- The components of ABS eight.0, particularly in connection with the ABS control unit/hydraulic unit assembly, should only exist replaced by specialist personnel with the appropriate specialist knowledge of the conditions for replacement and the Service Instruction.

- Only the new parts specified in the electronic parts catalogue should exist used equally replacement parts.

Hydraulic unit of measurement

When installed, the hydraulic unit is continued with the ABS control unit of measurement. On the version with ESP, the pressure sensor is no longer on the outside of the hydraulic unit of measurement, like on ABS 5.3 TC/ESP but instead is incorporated into the hydraulic unit of measurement. The individual components of the hydraulic unit cannot exist replaced or repaired. If there is a fault, either the entire hydraulic unit or the entire ABS command unit/hydraulic unit assembly has to be replaced.

The hydraulic unit's hydraulic connections to the primary cylinder are spaced differently for the ABS 8.0 and ABS eight.0/ESP versions. The diameters of the hydraulic connections also differ on the 2 versions. Information technology is therefore impossible to install the wrong version of the hydraulic unit of measurement.

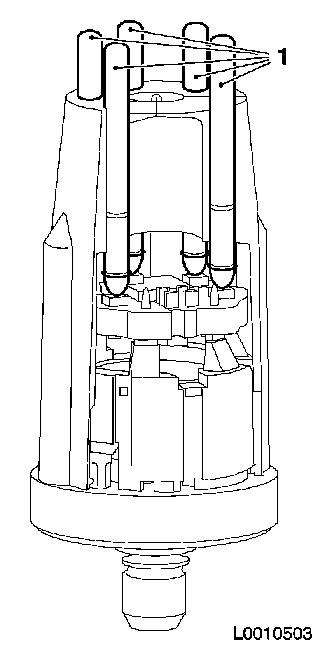

The spring contact pins located on the side facing the ABS control unit must not exist touched because of possible electrostatic discharge. Neither should measurements exist taken at them. The jump contact pins cannot exist replaced separately. Besides, to prevent impairment, the hard gold surface of the contact pins should non exist mechanically machined or treated with liquids such as contact spray.

No measurements should be taken at the connector contacts for the pump motor either. The contacts cannot exist replaced and are led in the lower section of the hydraulic unit through the valve block to the ABS control unit.

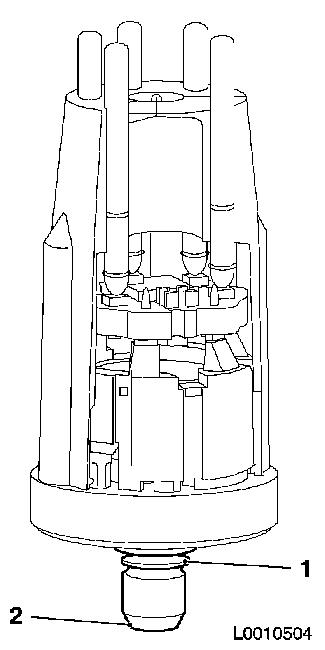

Pressure and temperature sensor - ABS 8.0 ESP

| Unlike on the ABS v.3 TC/ESP, the pressure sensor on the ABS 8.0 ESP is no longer on the outside of the hydraulic unit of measurement, but incorporated into the hydraulic unit of measurement instead. The electric connection to the ABS control unit of measurement is achieved using gilded coated bound contact pins. The pressure level sensor is attached to the hydraulic unit using a self-locking machinery (1) and cannot exist removed. The sensor is sealed off past means of the conical surface (two). The pressure sensor likewise incorporates a temperature sensor. The temperature sensor measures the temperature of the hydraulic unit of measurement. This information is used in the ABS control unit of measurement to assess the load on the braking arrangement past means of characteristic curves. For instance, the system assesses whether the braking system is about to overheat as a result of driving downhill. When driving downhill, the braking process causes the brake discs to heat up so much that the heat that is generated in the brake discs is transmitted via the brake calliper to the brake fluid. As a outcome, the temperature in the hydraulic unit rises as well. |  |

The pressure and temperature sensor has the following backdrop for all ABS control units:

- Selftest function

- Full self-diagnosis office with detection of sensitivity and offset errors

- 2 analogue outputs for force per unit area

- 2 digital outputs for temperature

Technical information for the pressure level sensor

| Pressure sensor measuring range: | (0 ... 250) bar |

| Temperature sensor measuring range | (-40 ...+120) °C |

| Power supply: | five V DC |

| • Service: The position of the pressure sensor must not exist inverse (due east.one thousand. by twisting). Neither should the sensor housing be subjected to mechanical loads, otherwise non-visible damage may occur. If there is a fault with the pressure sensor (apart from leaks), the entire hydraulic unit of measurement must be replaced. If there are still faults with the pressure sensor when the organisation goes back into functioning, the ABS control unit volition have to be replaced as well. If there is evidence of brake fluid loss at the pressure sensor, the unabridged ABS control unit/hydraulic unit of measurement associates will have to exist replaced as impairment to the ABS control unit by brake fluid tin can no longer be ruled out in this example. |  |

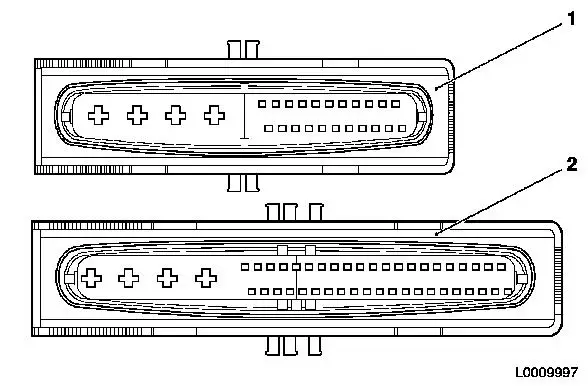

ABS control unit of measurement wiring harness plug

The plug connection on the ABS control unit is a 26-pin connector (ane) for the ABS eight.0 and a 46-pivot connector (2) for the ABS eight.0 ESP. For both variants, the wiring harness connector contains 4 power contacts with individual core seal. The size of the power contacts is (2.8 x 0.viii) mm.

ABS 8.0 also has 22 indicate contacts (42 for ABS 8.0 ESP), size (0.63 x 0.63) mm. The bespeak contacts are protected in the ABS command unit connector past a silicon seal.

After connecting them. the wiring harness connectors are locked past inserting the plastic pivot.

|

| Pin assignment - ABS control unit for ABS 8.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| Pin consignment - ABS command unit for ABS 8.0 ESP |

|

| Pivot | Assignment | Pin | Assignment |

|---|---|---|---|

| one | Earth | 24 | Not assigned |

| 2 | Battery + (last xxx) | 25 | CAN motorcoach: Signal line - yaw rate and steering angle sensor Likewise: With MTA: MTA point line Without MTA: BCM signal line |

| 3 | Battery + (terminal 30) | 26 | Not assigned |

| 4 | Earth | 27 | Rear left bike sensor |

| v | Front right bicycle sensor | 28 | Ignition + (final 15) |

| 6 | Front right wheel sensor | 29 | Rear right bicycle sensor |

| seven | Rear left cycle sensor | 30 | Brake light switch |

| 8 | Rear right wheel sensor | 31 | Not assigned |

| 9 | Front end left wheel sensor | 32 | Torso Command Module (BCM, Tin bus) |

| 10 | Forepart left bicycle sensor | 33 | Not assigned |

| 11 | Diagnostics connector | 34 | Not assigned |

| 12 | Non assigned | 35 | Engine control unit |

| 13 | Not assigned | 36 | Not assigned |

| 14 | Engine control unit | 37 | Non assigned |

| 15 | Not assigned | 38 | Not assigned |

| xvi | Non assigned | 39 | Not assigned |

| 17 | Non assigned | xl | Not assigned |

| eighteen | Not assigned | 41 | Non assigned |

| xix | Not assigned | 42 | Instrument cluster |

| twenty | Not assigned | 43 | Not assigned |

| 21 | Not assigned | 44 | Not assigned |

| 22 | Not assigned | 45 | Tin can bus: Signal line - yaw rate and steering angle sensor Too: With MTA: MTA point line Without MTA: BCM signal line |

| 23 | Not assigned | 46 | Not assigned |

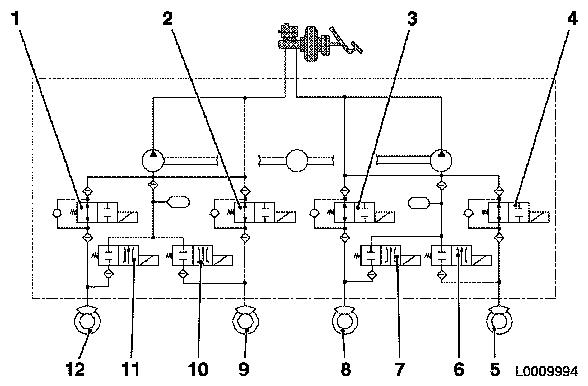

| Hydraulic system diagram - ABS 8.0 | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

|

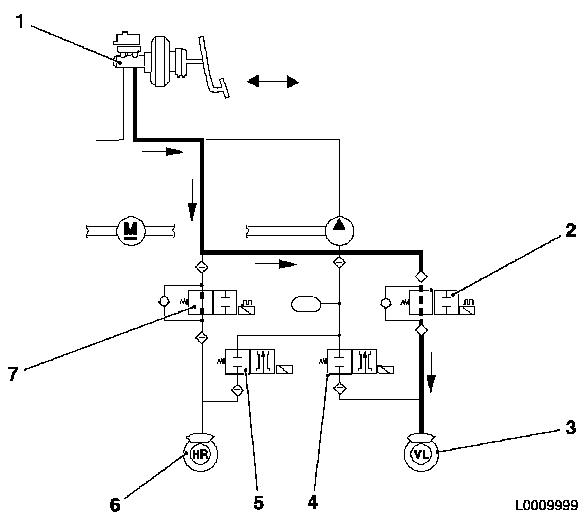

Haemorrhage the ABS eight.0 and ABS 8.0 ESP braking systems

Like on the Astra-G, the ABS 8.0 hydraulic system is bled in the post-obit sequence: rear right, rear left, front right, front left. The brake haemorrhage equipment bachelor from the "Service" department must exist used for this purpose.

The brake fluid goes into the reservoir and is pushed by the access pressure of the brake haemorrhage equipment through the master cylinder and the hydraulic unit into the wheel brake cylinder. The drain screw of the brake circuit being bled (hither the front end left excursion) is opened. All other bleed screws are airtight.

While the brakes are being bled, the initial pressure tin exist additional, thereby improving results, by operating the pedal. The respective brake circuits must exist bled until the brake fluid comes out without whatever bubbles or foam. The bleed operation is repeated in the same manner on the other iii wheels.

The following hydraulic diagram of the ABS 8.0 shows a normal bleed performance beingness carried out on the front left brake circuit.

| ||||||||||||||||

|

Electric data

| Software: | |

| Echo switch-on voltage after ignition ON | (ix.7 ± 0.iii) V |

| Undervoltage switch-off during regulation | (eight.nine...ix.6) V |

| Undervoltage switch-off exterior regulation menstruum | (9.2 ... 9.9) V |

| Overvoltage switch-off | (16.viii ± 0.5)Five |

| Hardware: | |

| Upper close-off threshold | (nineteen.9...23.five) V |

| Upper cut-in threshold | (20.vii ± 1.seven) Five |

| Lower shut-off threshold | (vi.9...7.8) V |

| Lower switch-on threshold | (7.v ± 0.4 5 |

| Overvoltage resistance of entire organisation | |

| with ignition ON, no operation | < 18 V |

| Duration | 1 h |

| at ambience temperature | (23 ± 5) °C |

| Jump starting time of unabridged system | |

| Overvoltage | < 24 V |

| Duration | five min |

| at ambience temperature | (23 ± 5) °C |

Hydraulic data

| Pump commitment rate per circuit in ABS performance | |||

| at a voltage at the pump motor of | (x ± 0.1) Five | ||

| with pump motor XS | > one.1 cm 3 /s | ||

| with pump motor S | > 1.5 cm three /s | ||

| with pump motor L | > 2.ii cm three /s | ||

| at a voltage at the pump motor of | (12 ± 0.1) V | ||

| with pump motor XS | > 1.8 cm iii /s | ||

| with pump motor S | > 2.2 cm 3 /s | ||

| with pump motor L | > 3.0 cm 3 /south | ||

| Pressure data: | |||

| Permissible operating pressure level | <200 bar | ||

| Maximum permissible pressure peaks during pump performance in chief circuit | < 250 bar | ||

| Minimum pressure level upward to outer leak in the | |||

| main circuit | 350 bar | ||

| Secondary circuit | 150 bar | ||

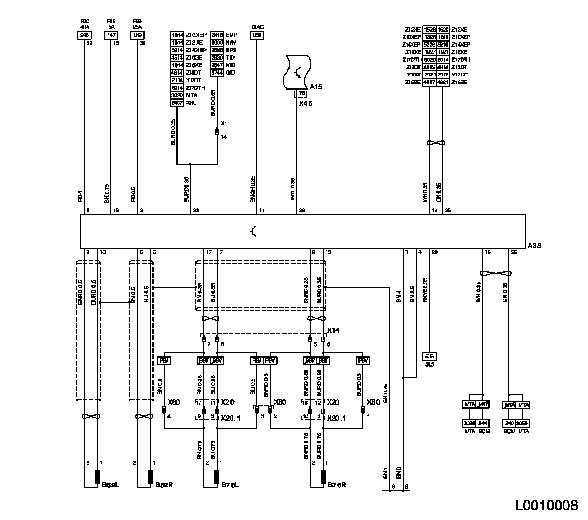

Wiring diagram - ABS 8.0

|

| Component | Description | Component | Description |

|---|---|---|---|

| BCM | Bodywork Control Module | Control units | |

| DIAG | Diagnostics connector | A15 | Bodywork Control Module |

| ECC | Electronic climate control | A38 | ABS control unit of measurement |

| EMP | Radio | Sensors | |

| EPS | Electric power steering | B52L | Forepart left wheel speed sensor |

| GID | Graphic Info Display | B52R | Front right wheel speed sensor |

| MID | Multi Info Display | B76L | Rear left wheel speed sensor |

| MTA | Automated-shift manual manual | B76R | Rear right bicycle speed sensor |

| NAV | Navigation organisation | Wiring harness connector | |

| PBV | Corsa-C Combo | X1 | Instrument panel and front torso |

| SLS | Brake light switch | X14 | Left-hand body |

| TID | Triple Info Display | X20 | Rear left trunk |

| TM | Telematics | X20.1 | Rear left body |

| WEG | Distance signal | X46 | Front end body and bodywork control module |

| XNL | Xenon headlamps | X80 | Rear left body |

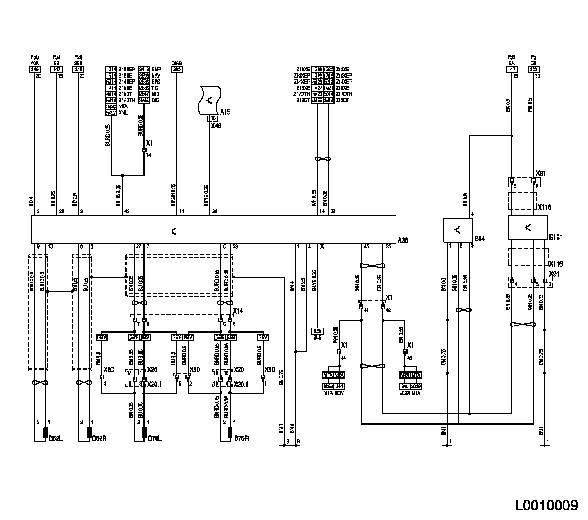

Wiring diagram - ABS 8.0 ESP

|

| Component | Description | Component | Description |

|---|---|---|---|

| BCM | Bodywork Control Module | Sensors | |

| DIAG | Diagnostics connector | B52L | Front left cycle speed sensor |

| EMP | Radio | B52R | Front right bicycle speed sensor |

| EPS | Electrical ability steering | B76L | Rear left wheel speed sensor |

| GID | Graphic Info Display | B76R | Rear right cycle speed sensor |

| MID | Multi Info Brandish | B84 | Yaw rate sensor |

| MTA | Automatic-shift manual transmission | B161 | Steering bending sensor |

| NAV | Navigation system | Wiring harness connector | |

| PBV | Corsa-C Combo | X1 | Instrument panel and forepart body |

| SLS | Brake light switch | X14 | Left-paw body |

| TID | Triple Info Brandish | X20 | Rear left trunk |

| XNL | Xenon headlamps | X20.ane | Rear left trunk |

| Control units | X46 | Front body and bodywork command module | |

| A15 | Bodywork Control Module | X80 | Rear left body |

| A38 | ABS control unit | X91 | Musical instrument console and contact unit |

| X116 | Contact unit | ||

Source: https://workshop-manuals.com/vauxhall/corsa-c/h__brakes/abs_8/description_and_operation/anti-lock_braking_system_(abs_8.0_and_abs_8.0_esp)/

Posted by: burkhardtinizing.blogspot.com

0 Response to "How To Repair Abs Control Module 08 G6"

Post a Comment